People & Culture

55 Years of SAMSUNG SDI’s Journey

2025.06.30

July 1, 2025 marks the 55th anniversary of SAMSUNG SDI’s founding. Established in 1970, SAMSUNG SDI has evolved from its beginnings in cathode ray tubes and display businesses to batteries and electronic materials. Let’s look back on 55 years of progress through 10 key milestones from its founding to the present.

The Beginning of SAMSUNG SDI’s History

January 1970: Established SAMSUNG-NEC Co., Ltd.

[View of the SAMSUNG-NEC Ulsan factory site]

On January 20, 1970, SAMSUNG-NEC Co., Ltd.—the predecessor of SAMSUNG SDI—was established. At the time, SAMSUNG sought to enter the electronics industry effectively through a technical partnership with NEC Corporation of Japan. Pursuing technological independence, the company later changed its name to SAMSUNG Electron Device Inc. in 1974 and to SAMSUNG SDI in 1999. This marked the beginning of SAMSUNG SDI’s journey to secure differentiated technology and top-tier quality.

The First Milestone in the Battery Business

July 2000: Completed the cell plant for the start of production

[‘Cell Plant Completion and SOP Ceremony’ at Cheonan factory]

SAMSUNG SDI’s battery business began in earnest in November 1997 with the operation of a pilot line at its Cheonan factory. In March 2000, the company completed construction of a dedicated battery facility at the same site and began trial production. By July, mass production was underway, and SAMSUNG SDI held a 'Cell Plant Completion and SOP Ceremony” attended by internal and external stakeholders. The mass-produced 2000mAh cylindrical battery outperformed the standard 1600mAh models commonly found on the market at the time. It demonstrated SAMSUNG SDI’s technological capabilities just three years after the pilot line launch.

Entering a Growth Trajectory in the Electronic Materials Business

January 2002: Completed the electronic materials production line at Gumi factory

[Electronic materials production line completion ceremony at Gumi factory]

SAMSUNG SDI’s electronic materials business gained full momentum in 2002 with the completion of a mass production line at the Gumi factory. The company first established production systems for key materials such as CMP slurry for semiconductor wafer polishing, EMC for semiconductor packaging, and electrolytes for batteries. In 2003, the expansion of the CMP slurry plant marked the beginning of broader business growth into semiconductor, display, and battery materials.

Full-Scale Launch of the EV Battery Business

November 2010: Completed the EV battery production plant in Ulsan factory

[Groundbreaking ceremony for EV battery production factory]

In November 2010, SAMSUNG SDI completed a 34,000 m² production line for electric vehicle (EV) batteries at its Ulsan factory. Construction began in September 2009 and was completed in just over a year. Mass production of EV batteries began in 2011. Even before the full-scale operation of the plant, SAMSUNG SDI had already secured an order with BMW for EV batteries, marking a significant achievement in the business.

World’s No.1 Small Batteries

December 2010: No. 1 global market share in small batteries

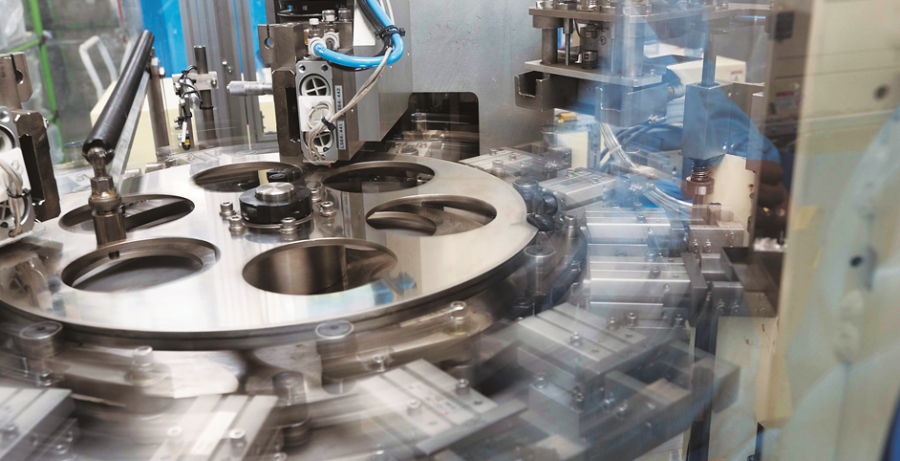

[The world’s first cylindrical battery high-speed assembly line with 200pm]

[The world’s first cylindrical battery high-speed assembly line with 200pm]

In 2010, SAMSUNG SDI sold 780 million small batteries, securing the No. 1 position in the global market with over 20% share. This achievement was the result of continued efforts, including the development of the world’s highest-capacity cylindrical batteries—2,400mAh in 2003 and 2,600mAh in 2004—and the launch of the world’s first 200ppm high-speed assembly line in 2007.

SAMSUNG SDI’s No. 1 market share in the power tool battery segment in 2010 (38%) also played a major role in securing its leadership in the small battery market. In 2004, SAMSUNG SDI identified power tools as an emerging market and began developing batteries specifically for power tool applications. Development was completed the following year, and the company steadily increased its market share thereafter. To this day, SAMSUNG SDI continues to maintain the No. 1 position in the power tool battery market.

Transformation as a Global Energy and Materials Company

July 2014: Officially launched merged entity of SAMSUNG SDI and Cheil Industries

[Headquarters of SAMSUNG SDI and Cheil Industries (Before the merger)]

On March 1, 2014, SAMSUNG SDI and Cheil Industries each held board meetings and decided to merge. SAMSUNG SDI aimed to strengthen its battery materials division to grow into a competitive energy company, while Cheil Industries was fostering energy materials as a new growth engine. The merger was seen as a strategic move to create synergy between the two companies. The legal procedures were completed on July 1, marking the official launch of the merged entity, and this date was designated as the new company’s foundation day. Leveraging the combined expertise in battery and electronic materials, SAMSUNG SDI emerged as a global energy and materials company.

Establishment of a European Manufacturing Base for EV Batteries

May 2017: Completed the EV battery plant at SDIHU

[View of SDIHU]

In May 2017, SAMSUNG SDI completed the construction of its EV battery plant in Hungary and began mass production the following year. As the EV market continued to grow, the need for a local manufacturing base in Europe became increasingly important to support new projects with European automakers. Today, SDIHU serves as a strategic hub for SAMSUNG SDI’s global customers.

Manufacturing Innovation through Smart Factory Development

June 1018: Started operating the battery ‘M Line’

[View of the ‘M Line’ at Cheonan factory]

To swiftly respond to the rapidly growing battery market, SAMSUNG SDI established a Mother Line (M Line) at its Cheonan factory in 2018. The ‘M Line’ for small-sized batteries began operation in June 2018, followed by the ‘M Line’ for medium- and large-sized batteries in September.

The ‘M Line’ enables pilot production of products before they are applied to mass production lines. This allows SAMSUNG SDI to verify mass producibility, process and equipment technology in advance. As the company expands its global production footprint, the ‘M Line’ ensures consistent performance and quality in mass production—anytime, anywhere.

Preparing for Future Business with Next-Generation Batteries

March 2023: Completed the all-solid-state battery pilot pine ‘S Line’

[View of the ASB pilot line at Suwon Office]

In March 2023, SAMSUNG SDI built a pilot line (S Line) of about 2,000 square meters at the SAMSUNG SDI Research Center to secure all-solid-state battery (ASB) technology. ASB features a solid electrolyte that facilitates lithium-ion movement between the electrodes, replacing the liquid electrolyte used in conventional batteries. They are called “dream batteries” because of their high energy density, long driving range, and safety. SAMSUNG SDI plans to secure not only research but also production technology for ASB through the ‘S Line’.

Expansion of Global Battery Production Bases

May 2022: Signed joint venture agreement with Stellantis

August 2024: Signed joint venture agreement with GM

[View of the Indiana plant of ‘StarPlus Energy’, the joint venture with Stellantis]

SAMSUNG SDI is targeting the global market through joint ventures with North American automakers. In May 2022, SAMSUNG SDI signed an MOU with Stellantis and established a joint venture, StarPlus Energy LLC., in December of the same year. The first EV battery plant located in Indiana, USA, began operations ahead of schedule in December 2024.

In August 2024, SAMSUNG SDI signed a joint venture agreement with GM and is currently constructing a plant in Indiana. By actively collaborating with automakers, SAMSUNG SDI is laying the groundwork to expand its market share in the North American EV market.

SAMSUNG SDI’s 55-year history has been a history of innovation. Since its establishment in 1970, the company has continuously enhanced its competitiveness in both the battery and electronic materials businesses.

In 2025, SAMSUNG SDI is accelerating its market expansion by diversifying its ultra-high-power cylindrical battery lineup through mass production of 46-phi batteries and supplying the SAMSUNG Battery Box (SBB) to Europe’s largest commercial ESS provider.

Moving forward, SAMSUNG SDI will continue to drive technological innovation as it prepares for the next 50 years.