Technology & Products

[SDI Focus] Tabless Technology: The Key to High-Power Batteries

2025.05.27

SAMSUNG SDI's tabless technology, which maximizes battery output, is drawing attention amid growing demand for high-power batteries in the power tool and the EV markets. Since March of this year, SAMSUNG SDI has been mass-producing high-power cylindrical batteries using tabless technology.

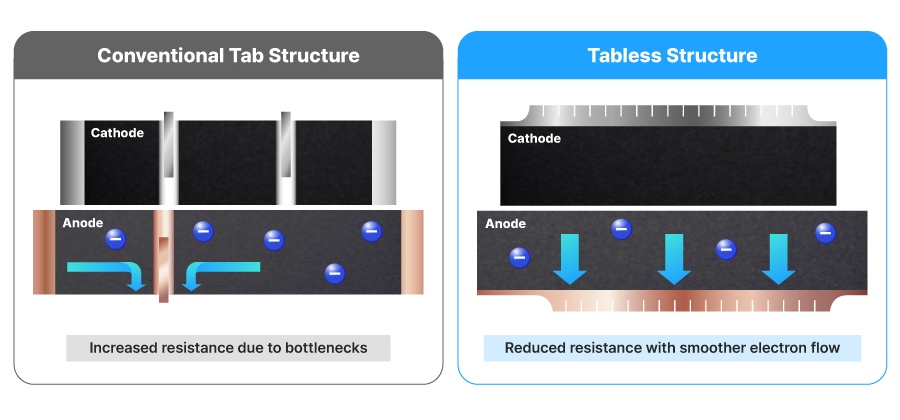

Tabless technology utilizes the electrode itself as a pathway for electron flow, reducing internal cell resistance and enabling high-power output. In conventional batteries, one or two tabs are attached to the electrode to conduct electrons. However, as the electrode length increases, electrons must travel longer distances in areas farther from the tabs, leading to higher internal resistance.

SAMSUNG SDI has replaced traditional tabs with the electrode itself, increasing the number of contact points for electron flow by tens of times compared to conventional designs. This broader pathway for electron movement has reduced internal cell resistance by more than half.

[Electron flow in conventional tab vs. tabless structure with SAMSUNG SDI's technology]

Low-resistance is beneficial not only for high-power output but also for fast charging. Lower resistance reduces heat generation during charging, enabling faster and more stable charge and discharge performance.

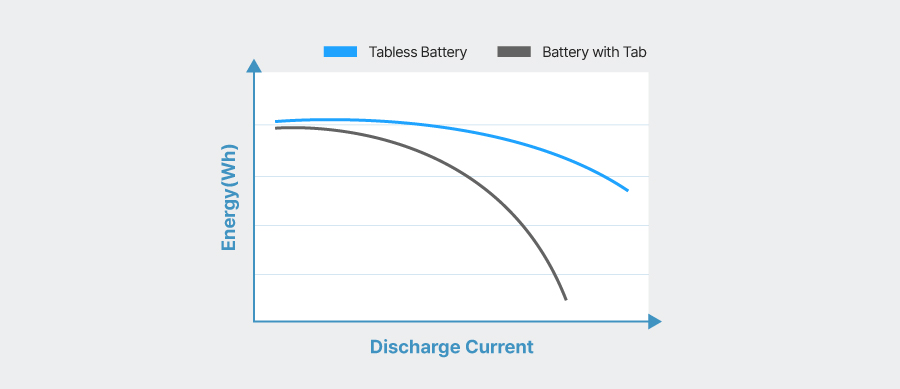

Energy loss due to higher discharge rates can also be minimized. Typically, as the discharge rate increases, more energy is lost to internal resistance, reducing the amount of usable energy. However, batteries with tabless technology experience less energy loss thanks to their lower internal resistance.

[SAMSUNG SDI's tabless battery with stable energy retention at high discharge rates]

During ultra-high power continuous discharge, heat can cause the battery to reach its temperature-cut threshold, limiting the usable energy. However, with tabless technology, the reduced internal resistance minimizes heat generation, thereby expanding the usable energy range. As a result, stable performance can be maintained even under conditions that demand high power output.

Based on these characteristics, SAMSUNG SDI is applying cylindrical batteries to various use such as power tools, EVs and OPE(Outdoor Power Equipment).

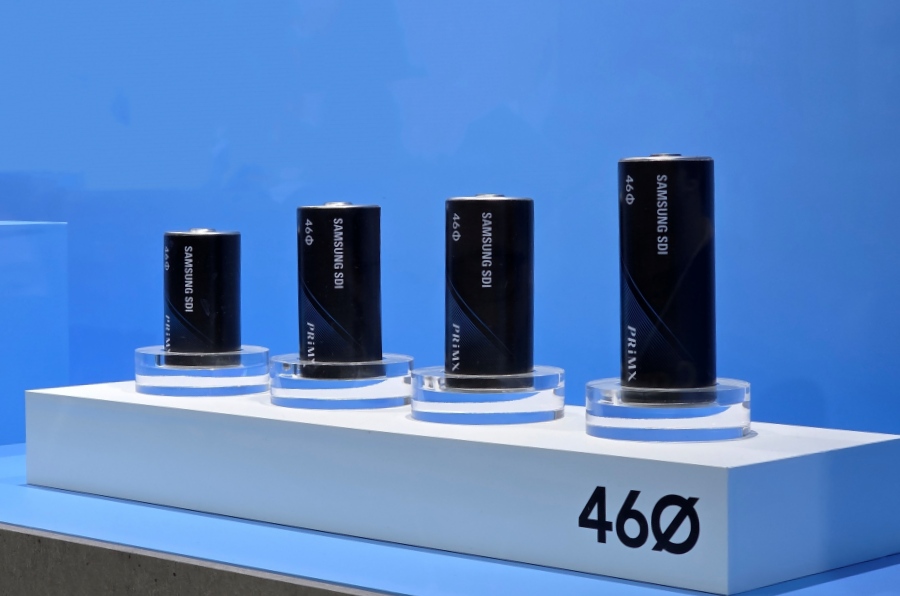

SAMSUNG SDI has already secured mass production capabilities for batteries featuring tabless technology. In March, the company began mass-producing 46 phi cylindrical batteries with reduced internal resistance through a tabless design.

[SAMSUNG SDI’s 46 phi batteries equipped with its tabless technology]

SAMSUNG SDI is integrating tabless technology across all premium cylindrical batteries in development, reinforcing its commitment to high-power innovation and next-generation market readiness.