Technology & Products

[SDI Focus] Confidence in Prismatic Battery, Built on Decades of Expertise

2025.05.15

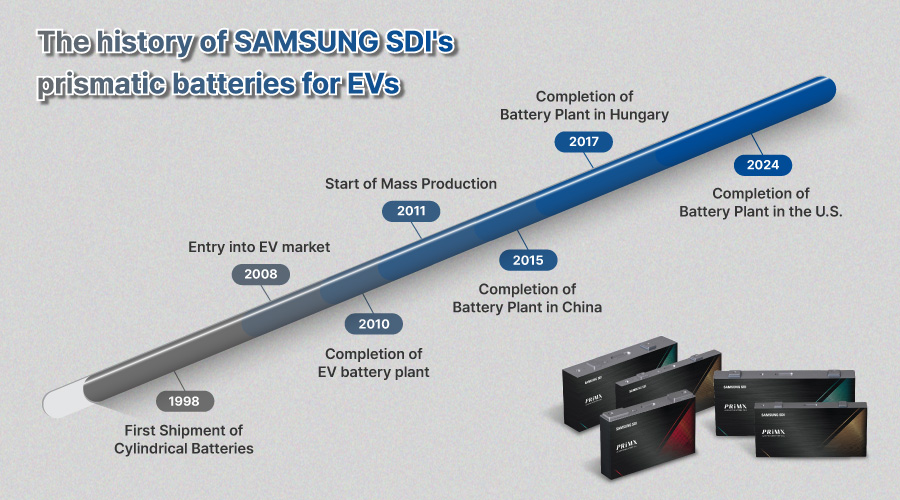

SAMSUNG SDI’s prismatic batteries for EVs are garnering significant market attention by achieving both high performance and safety. At the core of this success lies over 15 years of accumulated mass production expertise in prismatic EV battery technology.

[The SAMSUNG SDI’s prismatic batteries for EVs]

SAMSUNG SDI officially declared its entry into the EV battery market in 2008, a decade after it first shipped a 1,650mAh cylindrical battery—the highest capacity available at the time in 1998.

In 2010, the company completed construction of a dedicated EV battery plant in Ulsan and began mass production the following year, gradually building up its automotive battery manufacturing capabilities. Starting with China in 2015, SAMSUNG SDI expanded its global production lines to Hungary in 2017 and the U.S. in 2024.

While this global manufacturing system enabled faster customer response, the key challenge was to maintain consistent product quality across all locations. To address this, SAMSUNG SDI established the M-line at its Cheonan Factory in 2018 to advance its manufacturing technologies. This know-how was horizontally deployed across global sites, allowing high-quality products to be produced anywhere in the world.

[The history of SAMSUNG SDI’s prismatic batteries for EVs]

From the outset, SAMSUNG SDI chose the prismatic form factor for its EV batteries. It wasn’t the only available option. After cylindrical batteries, SAMSUNG SDI had also developed prismatic and pouch-type batteries for IT applications. However, Samsung SDI determined that safety was the most critical factor for EV batteries and chose prismatic cells as the form factor.

SAMSUNG SDI’s prismatic batteries feature an aluminum-can exterior structure, which offers exceptional durability and enhanced safety. The batteries are equipped with advanced safety design features, including vents and fuses.

More recently, SAMSUNG SDI has developed and incorporated its proprietary No TP technology to prevent thermal propagation between adjacent cells. This technology is applied not only at the cell level but also in modules and packs, further enhancing battery safety.

SAMSUNG SDI continues to build its technological capabilities to deliver batteries with both higher performance and improved safety.