People & Culture

[SDI Interview] Battery Materials Internalization Enhances Our Technology

2025.01.09

|

The SDI Interview features the stories of SAMSUNG SDI employees. It highlights their professional demeanor as experts in their work, while also showcasing their dedication to enjoying fulfilling lives through their hobbies during their free time. |

Batteries are composed of four major components—cathode, anode, separator, and electrolyte—as well as numerous other materials. Each material significantly impacts battery performance, making every components equally important. Through an interview with Pro Ki-wook Hwang and Pro Jae-jun Song, who are responsible for the “internalization of core battery materials”, we explore SAMSUNG SDI’s efforts in battery material development.

Q. Please introduce your role in battery material development.

Pro Ki-wook Hwang) We develop materials used in batteries. Our development is divided into two major parts: one focusing on materials for lithium-ion batteries and the other on materials for solid-state batteries. I am currently developing CNT dispersions for lithium-ion batteries.

Pro Jae-jun Song) I am responsible for developing materials to enhance the performance of solid-state batteries. Although I’m in my second year at the company, I’ve been involved in a wide range of tasks, from verifying and selecting raw materials for solid-state battery components to analyzing and inspecting these materials.

[Pro Jae-jun Song (Left) and Pro Ki-wook Hwang (Right) are responsible for battery material development]

Q. Why is battery material development so important?

Pro Ki-wook Hwang) The battery industry has been growing rapidly over the past few years, and the competition in technology is becoming increasingly fierce. In such circumstance, internalizing differentiated materials can provide the company with significant competitive advantages. Internalizing battery materials facilitates stable raw material supply and quality risk management, enables us to meet performance improvement demands, and helps maintain the confidentiality of proprietary technologies. Many battery companies are striving in various ways to internalize the core materials of batteries.

Q. What challenges do you face in material development?

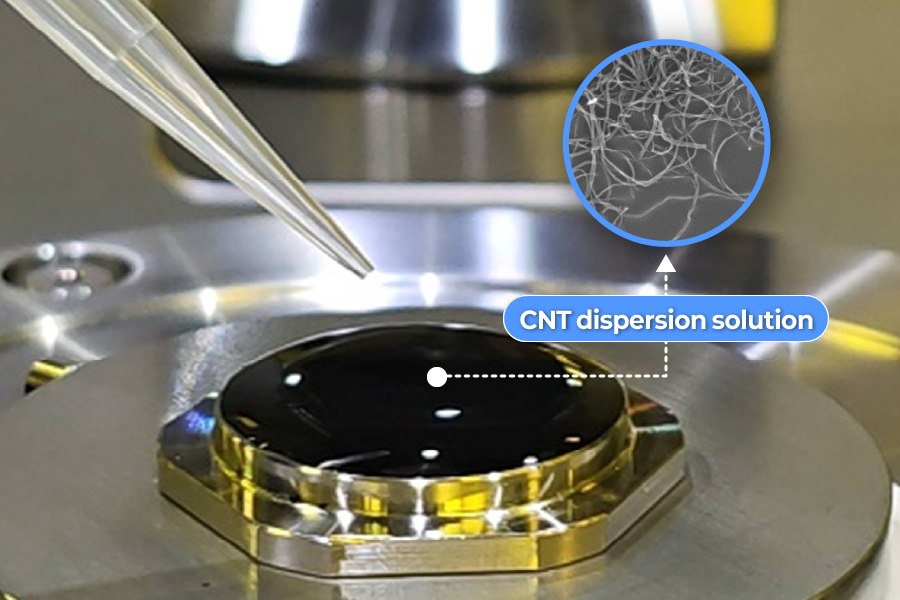

Pro Ki-wook Hwang) One major challenge has been thinking beyond my role as a developer to also consider business aspect. For example, during the material selection process, I had to evaluate production locations and profitability, which is unfamiliar to me as a developer. Additionally, because many of the materials we are working on are entirely new products that no one has developed before, there were lots of trials-and-errors. But, by communicating with many of our battery cell developers, we gained valuable insights. These efforts enabled us to successfully establish an M-Line at our Gumi plant in 2024 and manufacture CNT dispersion solution samples for various platforms.

[Magnified view of CNT dispersion solution]

Pro Jae-jun Song) For me, the challenge has been more personal. My parents have been excited to see me joining the company since day one. They often ask me, “What materials are you developing?” But because of confidentiality, I can’t tell them how my materials work in a battery and what experiments I do every day. I can only say, “I’m developing some kind of battery materials.” (Laughs) I look forward to the day when the solid-state battery materials become commercialized so that I can finally share my work updates with my family.

Q. Please share your determinations regarding battery materials development.

Pro Ki-wook Hwang) Everyone in our team is working their hardest with anticipation for new material developments. SAMSUNG SDI’s Electronic Materials Business has extensive experience and know-how in developing and mass-producing semiconductor and display materials. Based on this, I am confident we will succeed in internalizing core battery materials. Together with active business support, I am determined to achieve successful mass production.

Pro Jae-jun Song) Since we are developing materials that have never been made before, every experiment we conduct is unprecedented. While this is challenging, I find pride in knowing that the trial-and error processes will serve as milestones and guideposts for future battery material development. I am determined to internalize the core materials for next-generation batteries, ensuring our company secures unparalleled technological prowess in the battery industry.