People & Culture

[SDI Today] All 12 Worksites Earn Platinum level of ‘Zero Waste to Landfill’!

2025.01.03

SAMSUNG SDI’s all 12 worksites at home and abroad earned Platinum Validation, the highest rating under ‘the Zero Waste to Landfill (ZWTL)’ certification. ‘The Zero Waste to Landfill’ is a qualification system that validates the company’s efforts for zero waste and also an international standard for evaluating a company’s efforts for resource circularity. Awarded by UL Solutions, a global safety science certifier, ZWTL designations are classified into Platinum (100%), Gold (99-95%), and Silver (94-90%) ratings, according to the rate of landfill diversion a facility achieve.

[All 12 worksites earned Platinum Validations]

All six domestic operations have achieved the highest rating of Platinum. Giheung office and Cheongju factory earned Platinum for three years in a row, while those in Cheonan, Ulsan, Gumi and Suwon received the highest certification for two consecutive years. Of the total 70,000 tons of waste from all domestic operations, 99.64% of waste is recycled.

In 2024, all overseas worksites received Platinum Validations. SDIW(Wuxi), SAPB(Xi’an), and SDIV(Vietnam) earned Platinum Validations again this year, followed by 2023. SDIHU(Hungary), SDITB(Tianjin) and SDIEM(Malaysia) earned Platinum for the first time in 2024. These three sites were certified Gold in 2023, but in 2024, we committed to increasing its waste recycling rate to more than 99.5%.

SDIHU has achieved a resource circularity rate of 99.5% by categorizing mixed waste into different types of recycling methods. Among the mixed waste, ‘residual construction materials’ and glass waste, which are difficult to categorize in detail, are shredded and recycled into materials for road asphalt construction. Wood waste from the construction process is cleaned and dried before being recycled into furniture stores. Mixed packaging waste such as string, vinyl, and foil is cleaned, shredded, and used as a heat source for the production process through heat recovery.

[SAMSUNG SDI’s SDIHU in Hungary]

SDITB reduced its waste to landfill rate by switching from landfilling sludges* from wastewater treatment to recycling them as raw materials for bricks and asphalt. SDIEM increased its recycling circularity rate by changing from incinerating living waste from restaurants and offices to heat recovery.

* Residue that accumulates in sewage treatment plants

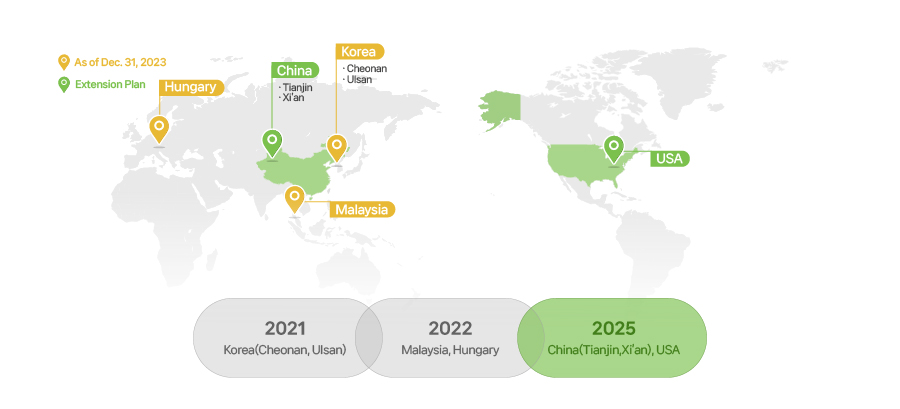

SAMSUNG SDI has continuously invested in waste recycling since 2019. We collaborated with recycling partners and established a recycling system of retrieving raw materials from process scraps generated from battery manufacturing. The metals are extracted from process scrap* not only from SAMSUNG SDI but also from customers and partner companies. Critical minerals extracted from process scrap are directly supplied to our battery material manufacturing partners and used again to manufacture SAMSUNG SDI products.

* Wasted material or metal scrap generated from the metal manufacturing

[SAMSUNG SDI’s plant scrap collection locations]

Achieving the ‘Zero Waste to Landfill (ZWTL)’ Platinum Validation at all SAMSUNG SDI’s worksites is the result of the company’s diligent implementation of ‘environment-friendly management’ since 2022. SAMSUNG SDI's ‘eco-friendly management’ is a strategy to achieve carbon neutrality by 2050 by focusing on specific tasks under the two themes of 'response to climate change and 'resource circularity’. SAMSUNG SDI will continue to actively strive to realize a sustainable and environmentally friendly future society.