Technology & Products

[SDI Focus] Why Is Dry Electrode Process in the Spotlight?

2024.11.19

In September, SAMSUNG SDI completed the ‘DryEV Line’, a pilot line for dry electrode production at the Cheonan plant, and started pilot production. The reason why SAMSUNG SDI has invested in the R&D of dry electrode production technology by establishing a pilot line is because it is one of the technologies to reduce facility investment cost.

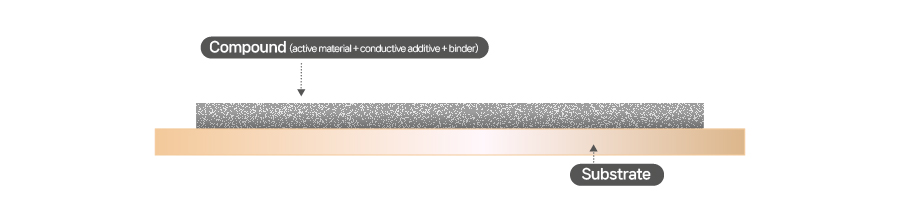

The manufacturing process of batteries consists largely of 3 big steps: electrode – assembly – finishing. Electrodes refer to cathodes and anodes, the core material of the battery. They are coated on the substrate* as cathode or anode active materials. Depending on how the active materials are coated on the substrate, there are two types of electrode manufacturing processes: wet and dry.

* Substrate : A thin metal plate that uses copper for the anode and aluminum for the cathode.

[Cathode and anode active materials are coated on the subsrate,

and there are two types of electrode manufacturing: wet and dry]

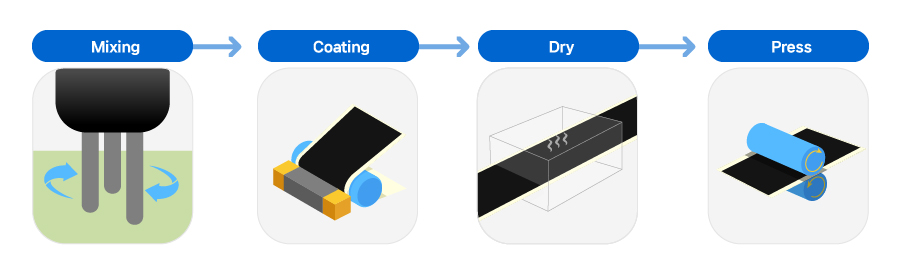

Most electrodes are manufactured through the wet electrode process. There are mainly 4 manufacturing steps: mixing – coating – drying – press. The process is called wet because cathodes and anodes active materials are mixed with a solvent to form a slurry, which is then coated onto the substrate.

This process can make more sense if you imagine spreading strawberry jam on bread. It’s hard to get the strawberries to stick directly to the bread, but it's easy with liquid strawberry jam. The idea is to make the anode and cathode active materials into a liquid slurry so that they can be well attached to the substrate, just like strawberry jam. However, this means that the wet process must be followed by a drying process. This is because when assembling the electrodes, a solid form is easier to handle than a slurry.

[Wet electrode process has 4 steps: Mixing - Coating - Drying – Press]

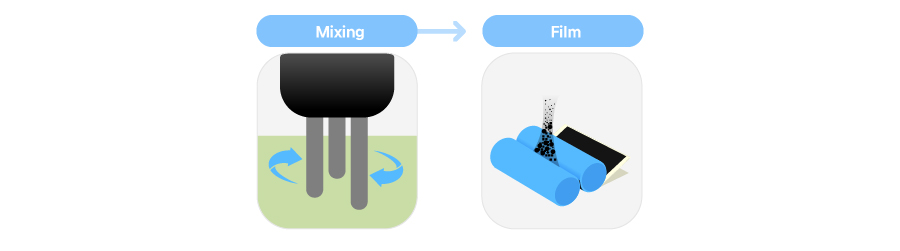

The dry electrode process is a simplified version of the wet process with two steps: mixing and filming. The anode and cathode active materials are made into solid powders, which are then made into a thin film and applied to the substrate. It's similar to making dough with flour, rolling it out thin and then forming long noodles.

The dry process does not require mixing the anode and cathode active materials in a solvent, nor does it require a drying process, which can significantly reduce facility investment costs and reduce power usage compared to the wet process.

[Dry electrode process is a simplified version of the wet process with two steps: mixing and filming.]

SDI will continue upgrading the dry electrode process technology through its ‘DryEV Line’.