Technology & Products

[SDI Focus] Can We Charge EVs to 80% in 9 Minutes?

2024.11.05

In March at “InterBattery 2024”, Samsung SDI was the first to unveil super-fast charging technology that can charge a battery cell from 8% to 80% in nine minutes. Charging speed is a crucial competitive factor in addition to price in the EV market.

Filling up an internal combustion engine takes around five minutes. However, charging an electric vehicle can take more than eight hours at slow speeds, or as little as 20 minutes at fast speeds for an 80% charge. If EVs can achieve the same charging times as their internal combustion engine counterparts, they will quickly win over consumers who are on the fence about choosing an EV.

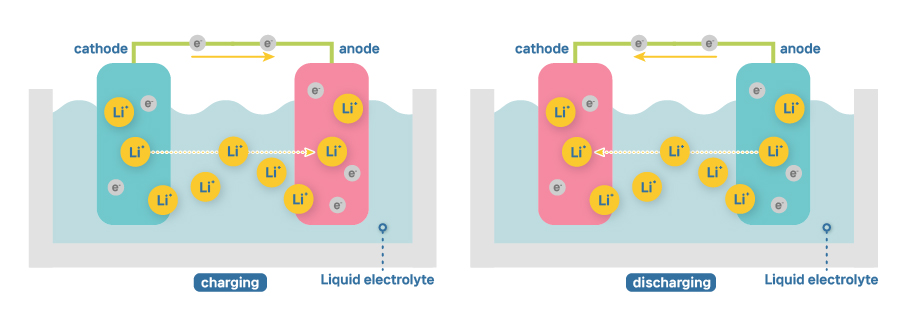

[Li-ion batteries are rechargeable through charging and discharging. When charging, Li-ions and electrons move from the cathode to the anode, and vice versa when discharging.]

Fast charging refers to a method of charging that delivers a higher electrical current faster than the current charging standard. Lithium-ion batteries charge as lithium ions move from the cathode to the anode. Fast charging technology will allow a large amount of Li-ions to flow in a short period of time. In other words, it focuses on how the technology can reduce the time and distance when ions are moving.

The key is to reduce internal resistance inside the battery cell in order to shorten the travel time and distance of lithium ions. High resistance prevents the lithium ions from moving around, which can have the adverse effect during rapid charging, reducing charging capacity and shortening battery life.

Samsung SDI has secured low resistance materials and electrode plate structure technology to realize fast charging battery cells by shortening the travel time and distance of lithium ions.

For low resistance materials, we are developing anode active materials that facilitate fast intercalation and deintercalation* of lithium ion and high-capacity silicon anode materials and electrode plate materials.

* Lithium-ion intercalation and deintercalation of anode active materials : When charging, lithium ions from cathode active materials are intercalated into the layered structure of anode active materials. When discharging, deintercalated lithium ions from the anode are absorbed in the cathode active materials.

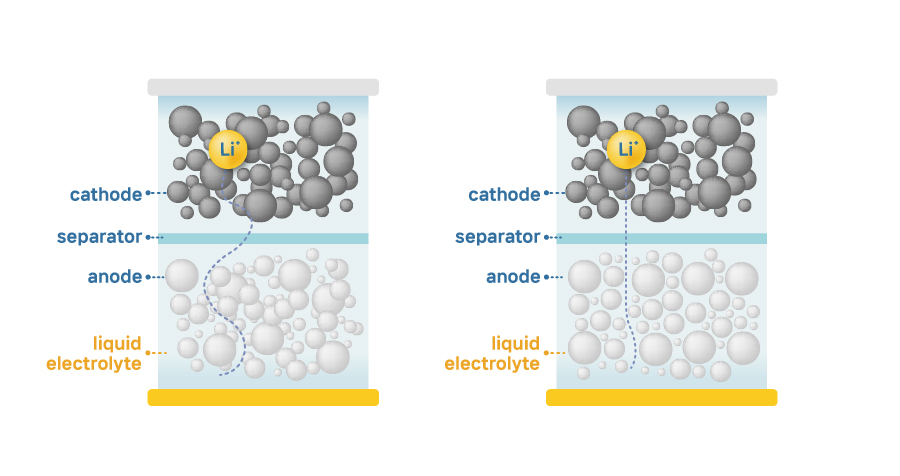

Electrode plate structure technology optimizes the travel path for lithium ions. For example, if you're at an outdoor concert full of people and one side of the crowd is standing in disorder and the other side is standing in orderly rows, which side is faster for a person at the back of the crowd to get to the front of the stage? Obviously, the side with the orderly rows.

If you think of the concert venue as a battery and the people going to the front of the stage as lithium ions, then the electrode plate structure technology is about making the standing people orderly, creating a pathway for them to move quickly.

[Fast charging technology shortens the travel time and distance of lithium ions. Electrode plate structure technology is one of fast charging technologies that offer an optimized path for lithium ions.]

Samsung SDI has a plan to incorporate fast charging technology into a battery by 2026. Commercialization of this technology will allow EVs to charge in 5 minutes and travel 300km.

* An average driver (approximately 99.6%) driver less than 300km a day.