Technology & Products

[Battery101] Rolling or Zig-zagging - Fun Battery Shapes

2024.06.21

|

101[wʌ́nouwʌ́n] means basic knowledge of a topic or collection of introductory materials to a topic. Our Battery 101 series talks about all things battery: the history, technical aspects (basic principles and mechanisms), industrial aspects (IT, electric vehicles, ESS, etc.), and next-generation technologies that SAMSUNG SDI will innovate while opening up its future. Batteries have infinite potentials that exceeds our wildest imagination. Through Batteries 101 series, you will have a chance to see the entire spectrum of the battery's possibilities and to conjure SAMSUNG SDI’s pivotal role in it. |

Three stages of making a battery

The best way to see how batteries are made is to visit factories in person. But those factory visits are not open for ordinary people. So instead of taking you to a battery factory physically, this issue of the Battery 101 series will guide you through how a battery is produced just like you're there to watch it!

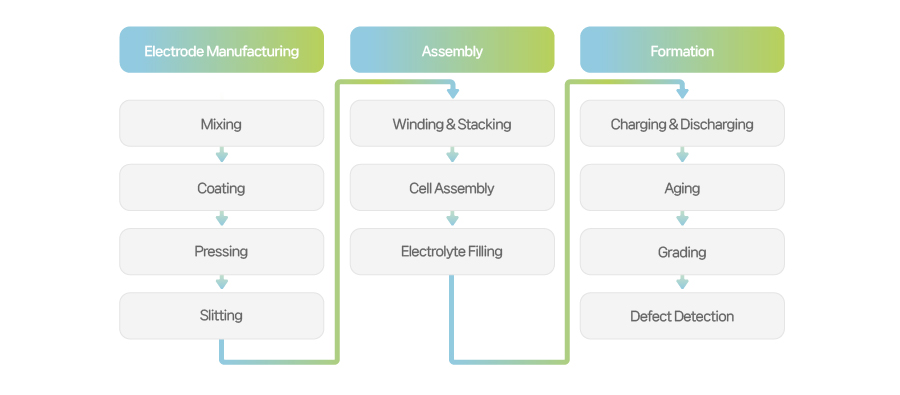

[Manufacturing of Lithium-ion Battery]

Lithium-ion batteries are manufactured through three main steps: electrode manufacturing, assembly, and formation. During the first step, positive and negative electrodes, cathode and anode respectively, are made. In the second step of assembly process, positive and negative electrodes and separators are assembled together in a metal can or a pouch by either winding or stacking with electrolyte filling. Next, the formation process put them under charging and discharging phases for final inspection. With electrode manufacturing, three types of batteries – cylindrical, prismatic, and pouch shape – all go through the same process whereas the details differ during assembly and formation steps.

Electrode manufacturing creates cathode and anode

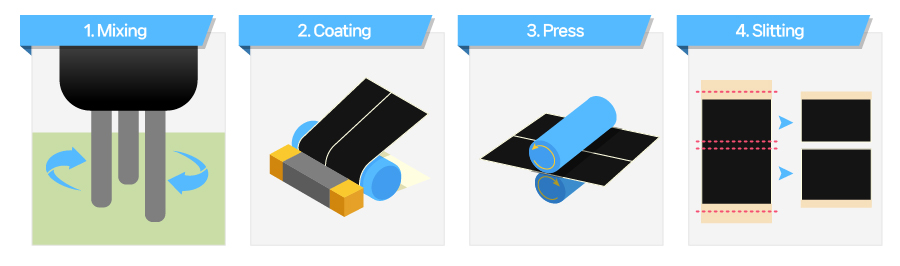

In this process, two of the four major components of a battery are made: cathode and anode. It begins with mixing, then coating, pressing and finishes with slitting.

[Electrode manufacturing]

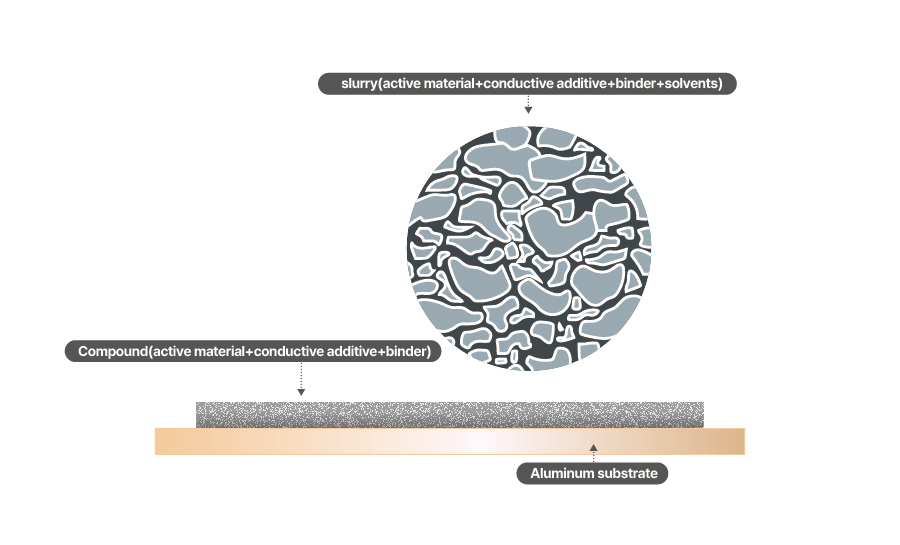

The mixing process is necessary to make a compound (mixture) that coats metal materials of cathode and anode. The compound is fabricated by mixing active materials, conductive materials and a binder: active materials for electrical performance of anode and cathode, conductive materials to make them conducive, and a binder to adhere metal ingredients and active substances. This compound is commonly known as ‘slurry’. When the compound is made, it is then coated evenly on the aluminum foil and the copper foil which are substrates for cathode and anode, respectively. The result looks like those foils have been painted black.

[Substrate and compound]

Pressing makes the metal electrodes and the compound stick together and the layer thinner so that the electrodes have better density and adhesion to the substrates as well as facilitated ion transport. Next comes the slitting process where the pressed electrodes get sliced into reels, finalizing the whole electrode process.

All these four elements are put together to make a battery

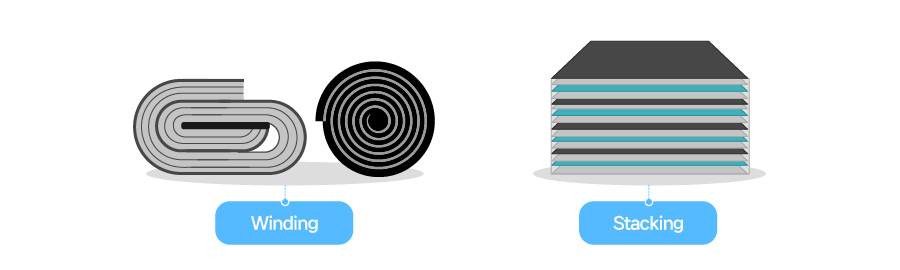

The assembly process completes a battery by putting a separator between cathode and anode. The electrode manufacturing process is categorized into two parts. “Jelly roll” or stack is made by either winding or stacking cathode and anode materials in turn between separators. This jelly roll is then packaged into a pouch or in a metal can, which is either sealed or welded, followed by electrolyte filling.

[Stacking methods]

As the battery assembly line is fully automated, detecting a problem or a defective cell is automatically done as well. If there’s a deviation from the settings, an alarm goes off to inform line workers whereas defective cells, once detected, are stopped from passing through to the next stage. Only batteries with perfect performance and quality can move on to the next process.

Formation brings life to batteries

In the formation process, assembled batteries are embedded with electrical properties and examined for defects. Lithium-ion batteries fresh out from the assembly process do not load any voltage. They need to be charged first to be able to function as a proper battery. The formation process comprises of charging and discharging, aging, grading, and outgoing inspection, in this order.

Going through cycles of charging and discharging, which accounts for over 80% of the formation process, makes a discharged battery activated. During this stage, a thin layer of solid electrolyte interphase (SEI) is formed on the surface of the anode electrode. This passivation layer plays a vital role in resulting performance and lifespan of batteries.

The aging process is where batteries undergo gradual maturing at predetermined temperatures and humidity. This is when electrolytes from the solid electrolyte interphase film get dispersed evenly inside a battery so that lithium ions can move as desired.

In addition to repeated charging and discharging cycles, voltages, resistance and capacity of batteries are inspected in the formation process. This is called outgoing inspection, the final quality gate of the battery manufacturing process.