Technology & Products

[Battery101] Form of Battery

2024.05.31

|

101[wʌ́nouwʌ́n] means basic knowledge of a topic or collection of introductory materials to a topic. Our Battery 101 series talks about all things battery: the history, technical aspects (basic principles and mechanisms), industrial aspects (IT, electric vehicles, ESS, etc.), and next-generation technologies that SAMSUNG SDI will innovate while opening up its future. Batteries have infinite potentials that exceeds our wildest imagination. Through Batteries 101 series, you will have a chance to see the entire spectrum of the battery's possibilities and to conjure SAMSUNG SDI’s pivotal role in it. |

Batteries have three form factors

These days, so many devices are powered by batteries that it’s much easier to think of devices that aren’t. As diverse as the size, battery life, and purpose of those devices are, there are also many forms of batteries. So the battery industry decided that three forms of batteries would be used for efficient production: cylindrical, prismatic, and pouch cells.

[Various battery forms by SAMSUNG SDI]

Cylindrical, prismatic and pouch cells have their own characteristics that set themselves apart from one another. Cylindrical cells, to start with, enable mass production for higher productivity and low prices. However, this also means that they lack flexibility to be turned into sizes that you want. Pouch cells boast flexibility in sizes and capacity but are less attractive than cylindrical cells when it comes to mass production, having lower scores in both productive and price aspects.

Since each of these battery forms vary in output, safety, and manufacturability as well as application, productivity, prices, you need to take many factors into considerations such as characteristics of a device requiring a battery and customer’s needs. Close communication with customers is a must for battery makers as they need all the information on specific applications of a battery in order to come up with optimized solutions for the customer.

Small but powerful – cylindrical cells

When we think of a battery, we generally think of a cylindrical cell, which is a type AA battery. The first mass-produced lithium-ion battery also happened to be a cylindrical cell. These round-shape cells come in small sizes, making them a handy installation for small IT devise. Because they feature high capacity and high energy, nowadays, they have expanded their application to gadgets that require instant high output.

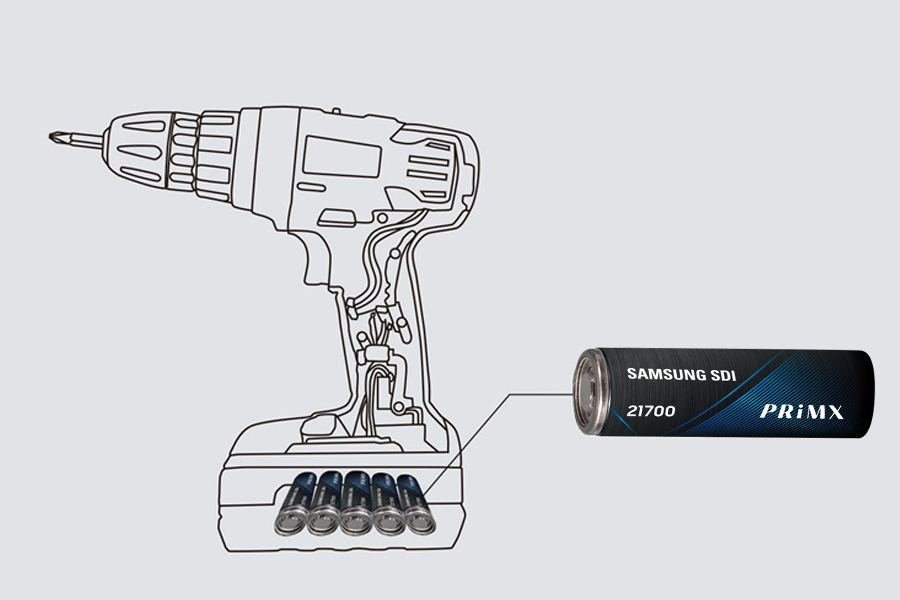

[Cylindrical batteries installed in a power tool]

Gadgets that need instant reaction in powering, like power tools, robot cleaners, and gardening tools, run on cylindrical cells. Power tools, in particular, must have such feature because they drill through concrete, cut through wood, or do metal-working. Not only that, they should be long-lasting, high-capacity, and extra safe for a user’s sake. Particular importance is weighed on the abilities to handle vibration and prevent spark or any harm to a user in case of sudden high electrical loads for these power tool batteries. Cylindrical cells are the best choice to meet all those criteria, which is why they are loved for so long.

Another characteristic of cylindrical cells is their standard formats, which mean they can be mass-produced with lower prices and therefore have wider applications. However, due to their roundness, cylindrical cells falls short in geometrical efficiency when packed together, resulting in less favorable capacity and energy density.

Strong resistance to shock and heat – prismatic cells

Prismatic cells are encased in aluminum and shaped like a prism. They are thicker than cylindrical cells and have higher shock resistance than their pouch counterpart.

Prismatic cells in electric vehicles are now slightly larger than the palm of a hand, but when they first appeared they were much smaller than that because they were used in portable cell phones. In 1983 when the first cell phone was introduced, its nickname was a ‘brick’ phone for its enormous size. The advancement of various technologies helped the size of cell phones to be tiny enough to hold it in a hand and one of those technologies is that of a battery.

Until the mid-1990s, the batteries in mobile phones were nickel-metal hydride batteries. It wasn't until these were replaced by lithium-ion batteries that mobile phones were able to become thinner and lighter. At the time, mobile phone batteries were removable and interchangeable, and Samsung's logo-emblazoned square batteries were a big hit. The popularity of square batteries didn't stop with mobile phones, but also found its way into slim laptops.

However, with the advent of thinner smart devices, the use of prismatic batteries has declined. The rise of smartphones, for example, has been a major blow to prismatic batteries. The demand for batteries that can be freely shaped and sized has increased, and pouch batteries have become more popular.

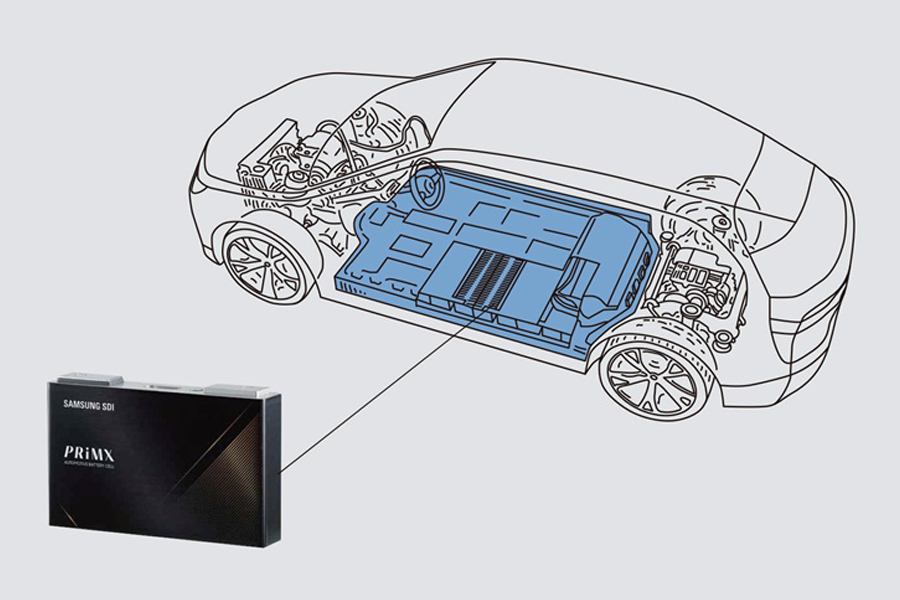

[Prismatic cells in an electric vehicle]

Prismatic batteries are in high demand for EVs. Putting safety as the top priority, electrified vehicles met prismatic cells as their suitable match as these rectangular-looking cells feature a high level of structural safety and good heat dissipation. Other advantages include being geared with a myriad of safeguarding elements such as a vent that lets out internal gas and a fuse that cuts off the circuit in the event of particular electrical currents.

Versatilities – pouch cells

Pouch cells are encased in soft, reflective, and thin film, which is quite a contrast to their pouch and prismatic counterparts that have metal casing. Due to such characteristics of their package, pouch cells make it possible to manufacture flat, wide batteries: design flexibility which also increases their space efficiency and energy density.

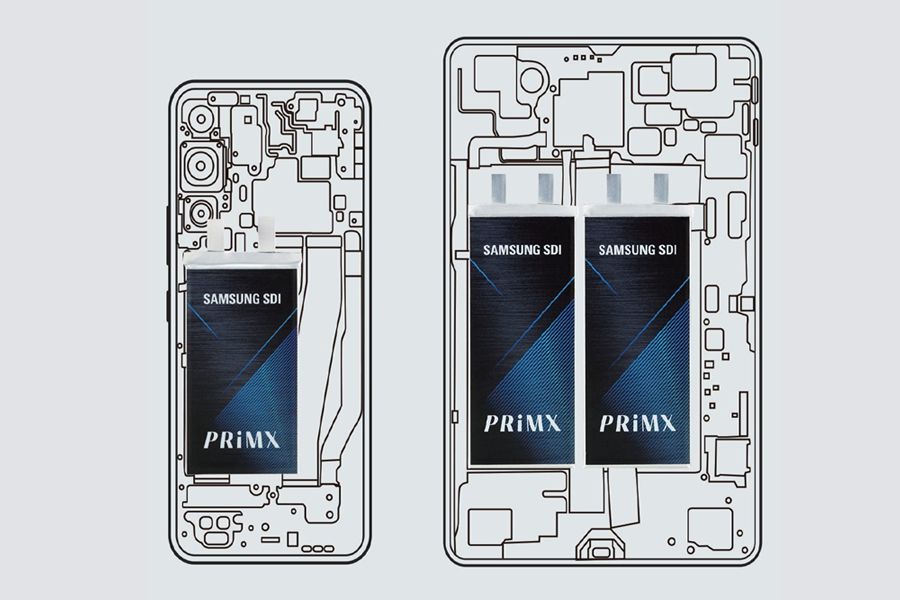

[Pouch cell in a smartphone and a tablet PC]

Pouch cells have advantages in light weight, and versatile sizes and capacity, making them a popular choice for slim IT applications. As a result, many IT devices that run on pouch cells, such as smartphones and tablet PCs, have overcome their thickness limitations and garnered a lot of attention.

Pouch batteries are still widely used in a variety of IT devices. More recently, they are also being used in electric vehicles. While less than 10 pouch batteries are typically used in IT devices, hundreds are used in electric vehicles, so safety is paramount. In particular, the nature of the pouch makes it vulnerable to external shocks, which requires pertinent technologies to organize them into modules or packs, making them relatively expensive.