Technology & Products

[Battery101] Cell, Module, and Pack of Batteries

2024.08.30

|

101[wʌ́nouwʌ́n] means basic knowledge of a topic or collection of introductory materials to a topic. Our Battery 101 series talks about all things battery: the history, technical aspects (basic principles and mechanisms), industrial aspects (IT, electric vehicles, ESS, etc.), and next-generation technologies that SAMSUNG SDI will innovate while opening up its future. Batteries have infinite potentials that exceeds our wildest imagination. Through Batteries 101 series, you will have a chance to see the entire spectrum of the battery's possibilities and to conjure SAMSUNG SDI’s pivotal role in it. |

Batteries define the performance of a module, pack and EV

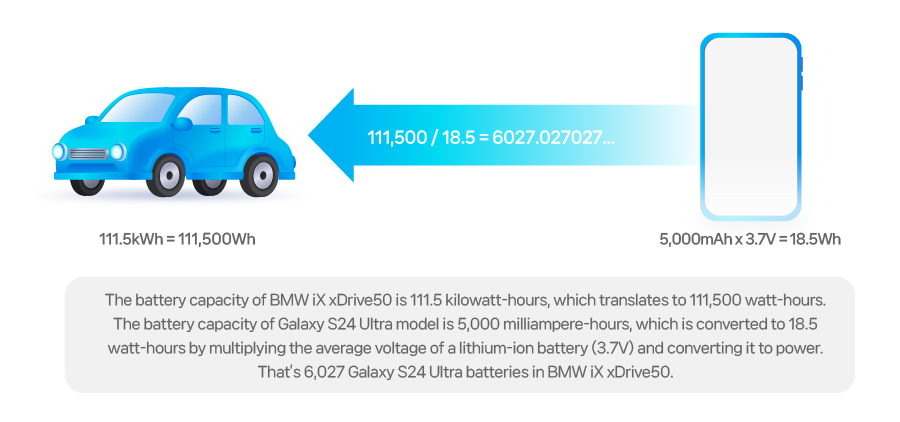

“How many smartphone batteries do we need to power an EV?” As a rule, an electric car contains about 6,000 smartphone batteries.

[Battery capacity of electric vehicles]

However, when you open up an electric car, you don't see the thousands of batteries that you might imagine, because they're organized into modules and packs for safety and management.

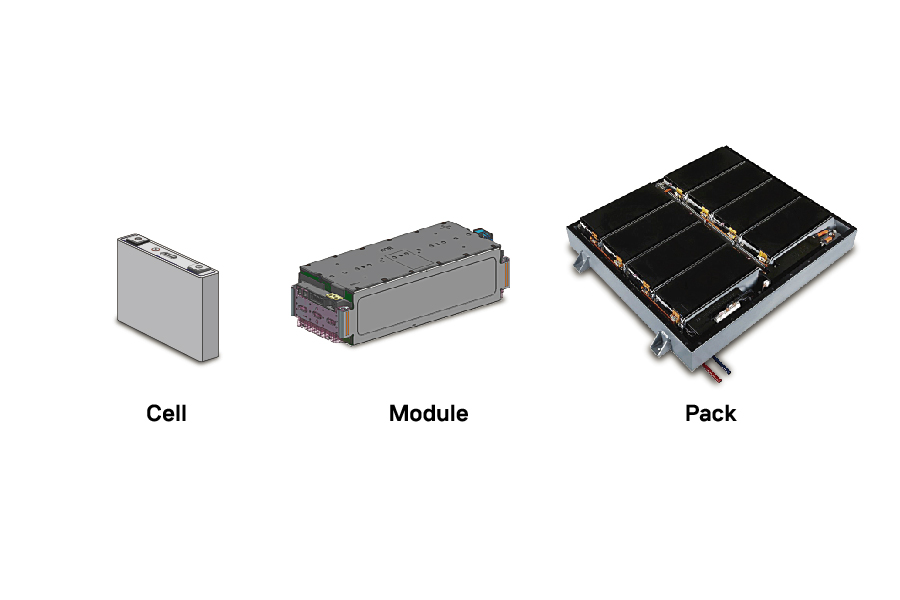

Generally speaking, when we talk about batteries, we mean “cells”. A cell is the basic unit of a battery. In applications that require large capacity batteries, such as EVs, it's inconvenient and difficult to manage cells one by one. In order to manage cells safely and efficiently, we group a large number of cells into a unit and call it a “module”. Several modules with dozens of cells together are called a “pack.” In other words, cells, modules, and packs are units that refer to a batch or bundle of batteries.

[Cell・module・pack for EV batteries]

BMW iX xDrive50 model is equipped with 500 prismatic cells, but instead of having 500 cells individually, we take 40 or 50 cells and make them into a module, and then we put 11 of these modules together to make a battery pack. Modules and packs exist to ensure safety. EV batteries especially require high energy density so that they can best perform in limited spaces. At the same time, batteries should withstand external shocks and tolerate temperature changes.

Modules provide a robust frame that protects the cells from external shocks, such as heat and vibration. They house slave battery management systems (BMS) that can monitor the status of the cells. A pack, the final form of a battery, is equipped with the master BMS that manages temperature, voltage, and more. Here, the system also includes cooling equipment and various controls to protect against fire and accidents. The BMS in modules and packs plays a variety of roles, including measuring the remaining capacity of the battery, balancing, operating the auxiliary circuit, communicating with the main unit (vehicle), and preventing accidents. It helps to ensure that the battery remains in optimal condition as its capacity and voltage degrade during charging and discharging.

The configuration of modules and packs is directly linked to efficient design and structure of electric vehicles. And the development of modules and packs is also receiving growing attention as it affects performance and design of a vehicle. Modules and packs play a crucial role in that they are more than just the outer casing that surrounds the cells.

Safety is the top priority

Safety is the one thing that’s the most emphasized in every car, not just EVs. As we see more and more EVs on the road, battery safety has become a hot topic. In fact, batteries for EVs contain multiple levels of safety devices, carrying out a number of safety assessments to ensure safety.

What is the key to battery safety? It is to prevent the anodes and cathodes from touching, as this can cause fires and explosions due to short circuits. In the event of a car accident, a strong external impact can damage the battery, leading to a very dangerous situation. For this reason, safety devices at all levels are designed to prevent short circuits caused by a contact between a cathode and an anode when the stability of a battery structure collapses.

The most basic of these is to ensure the safety of the cells. An explosion or fire at the cell level can quickly spread to modules and packs. As previously mentioned, Positive Temperature Coefficient (PTC), Current Interrupt Device (CID) and vents come into play; PTC inhibits electrical current to protect against overcurrent, and CID interrupts electrical current in the event of gas release and high pressure. And vents release gas to prevent explosion.

The main safety device designed in modules and packs is battery management system (BMS). It is responsible for detecting and preventing overheating and overcharging. BMS is essential for safety because it provides the vehicle with information about the battery's temperature and voltage, allowing it to detect a temperature rise and make a charging balance. Especially, overheat and overcharge are considered the most dangerous in a battery, so this system is essential to ensure safety.

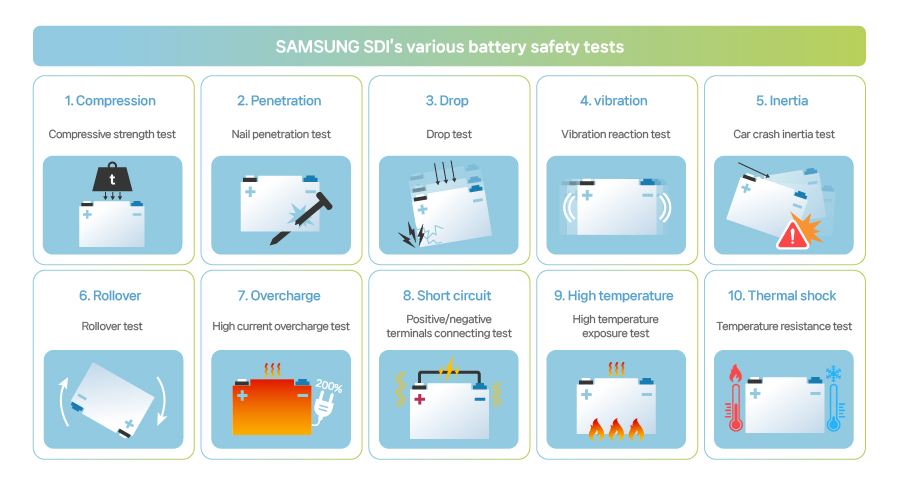

Moreover, battery companies are working hard on safety testing to prepare for any unexpected accidents. The most common safety testing include compression, penetration, drop, vibration, overcharge, short circuit, high temperature, and thermal shock. In addition, because EV batteries are larger in capacity and size than small batteries, they require more stringent acceptance criteria, such as inertia and rollover safety verification testing. As physical shocks and rollover accidents are the most common hazardous situations for EVs, the same situations are simulated to test safety.

The Korea Transportation Safety Authority announced that from 2022, it will conduct battery safety verifications on insulation, operation and high-power electrical devices. Battery testing has been added to the existing visual inspection and insulation resistance inspection. SAMSUNG SDI conducts battery safety tests in a 1,900-square-meter laboratory built of special concrete with walls as thick as 40 centimeters, and is designed to withstand the simultaneous explosion of more than 50 TNT. SAMSUNG SDI is proud to say that we put a great deal of effort into safety assessments for the best quality.

[SAMSUNG SDI’s various battery safety tests]