Technology & Products

[Battery101] Emerging Next-generation Battery

2024.10.11

|

101[wʌ́nouwʌ́n] means basic knowledge of a topic or collection of introductory materials to a topic. Our Battery 101 series talks about all things battery: the history, technical aspects (basic principles and mechanisms), industrial aspects (IT, electric vehicles, ESS, etc.), and next-generation technologies that SAMSUNG SDI will innovate while opening up its future. Batteries have infinite potentials that exceeds our wildest imagination. Through Batteries 101 series, you will have a chance to see the entire spectrum of the battery's possibilities and to conjure SAMSUNG SDI’s pivotal role in it. |

The emergence of next-generation batteries

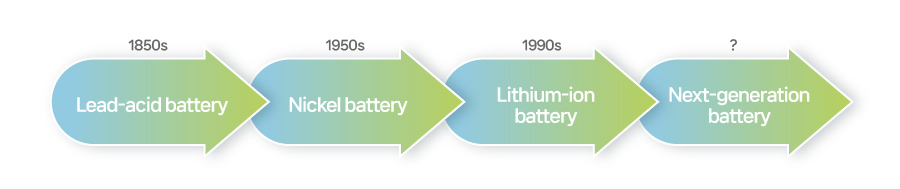

Generation refers to a period of time between the birth of an organism and the end of its life. Batteries have also evolved over several generations. Today, lithium-ion batteries are called as the “third-generation batteries.” Let’s find out what the first and second generation batteries were like.

The first generation battery is lead-acid batteries which have been around since their mass-production in the 1850s. Even today, they are still prevalent for starting internal combustion engines, and their affordability is their biggest merit. Second generation batteries are nickel-metal hybrid, nickel-cadmium, and nickel-zinc. Nickel batteries sent a shock wave around the world because of their higher density compared to lead-acid batteries. Nickel-cadmium batteries, in particular, were in high demand in the 1950s after being applied to power tools and small home appliances.

The most popular lithium-ion batteries in use today are third generation batteries. Since their introduction in 1991, lithium-ion batteries, which have twice the energy density of nickel-cadmium batteries and are easier to charge, have been adopted in a wide range of applications, from electronics to automobiles. However, it’s been already 30 years since the introduction of lithium-ion batteries. Considering that a typical human lifespan is 30 years, it seems only natural that next-generation batteries would arrive.

Next-generation batteries are the rising star that will overcome the capacity limitations of lithium-ion batteries and solve the safety issue. To date, the industry of secondary batteries has gone through four stages: technology development, market creation, business competition, and product development. Next-generation batteries are still in the technology development stage, but will continue to evolve through the four stages.

Overcoming the limitations

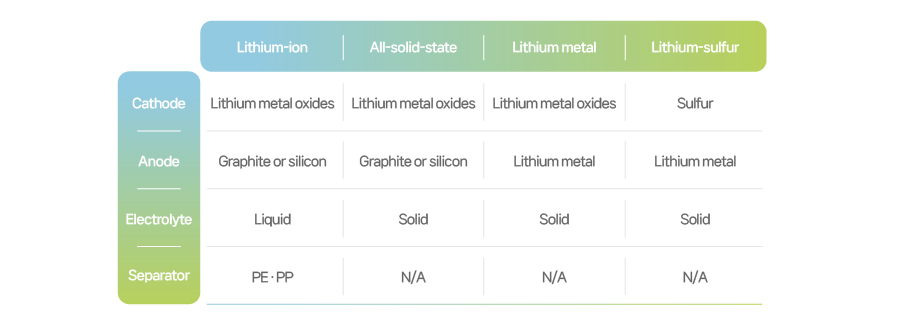

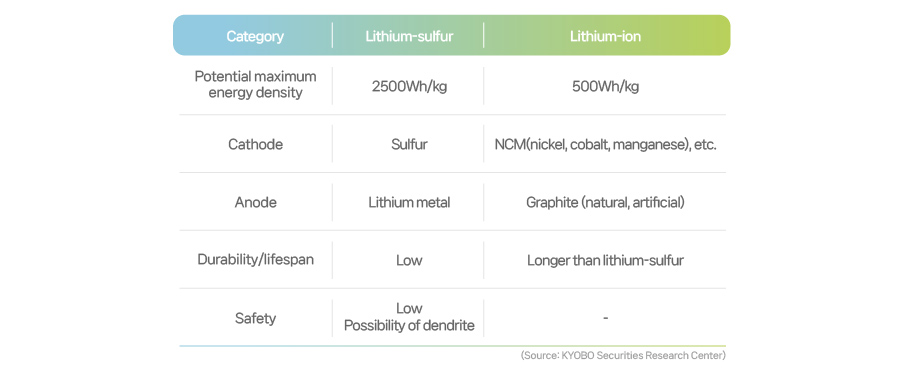

The table below is a comparison between the three different types of next-generation batteries that are rising.

[Comparison between LIB and next-generation batteries]

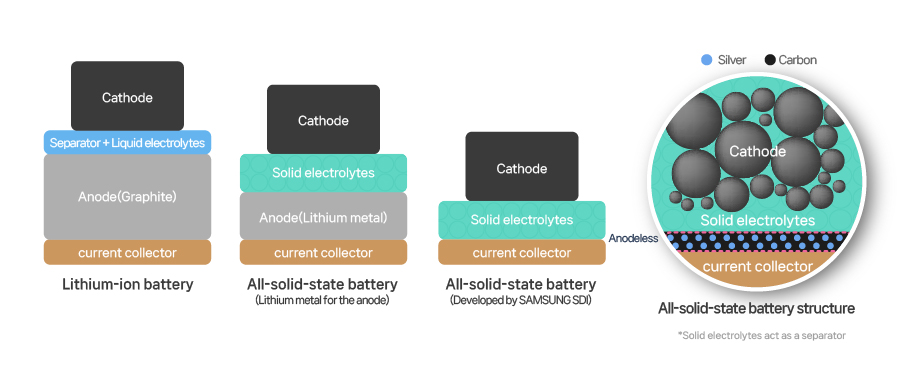

All-solid-state battery (ASB) is probably the closest to commercialization among all next-generation batteries. Accordingly, a lot of companies are investing in various ASB development. Then, what are the changes that ASB can bring about? What we expect the most is stability. Because Li-on batteries use liquid organic solvent as their electrolytes, there is the potential for the battery to swell due to temperature changes or catch fire in the event of external impacts. However, when it comes to ASB, risks are very low because they use solid electrolytes. In addition, the need for a separate cooling device or BMS in modules or packs can be greatly reduced as ASB can normally operate under extreme external conditions such as heat or pressure. This can ultimately increase the energy density of an EV battery.

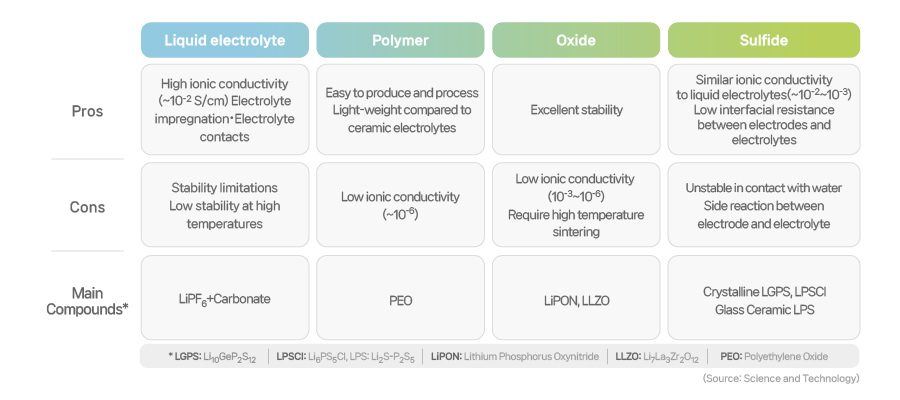

All-solid-state batteries use a solid electrolyte and can be divided into three types depending on the component of the electrolyte: Polymer, Oxide, and Sulfide. Polymer electrolytes are easy to produce but have a low ionic conductivity and degrade in low temperature environments. Oxide electrolytes have excellent stability and relatively high level of ionic conductivity, but require a high temperature sintering, which hinders their large-scale utilization and mass-production. Sulfide electrolytes have a high ionic conductivity and a low interfacial resistance, but are usually unstable in humid air, which readily absorbs water and releases gas. Despite these difficulties, many companies have focused on studying sulfide electrolytes because they are known to be the best material to date.

[Pros and cons of each electrolyte type]

In fact, the ‘all-solid-state battery’ itself may not be the next-generation battery, because it will need to have a higher energy density that pushes the capacity limits of Li-ion batteries, and simply replacing liquid with solid electrolytes is not going to provide a dramatic ‘energy density boost’. That's why recent research into next-generation solid-state batteries has focused on changing the active materials of the cathode and anode and using a solid electrolyte. The most representative types are lithium metal and lithium-sulfur batteries, which are currently under development with the goal of using solid electrolyte and changing active materials at the same time to ensure safety and increase capacity.

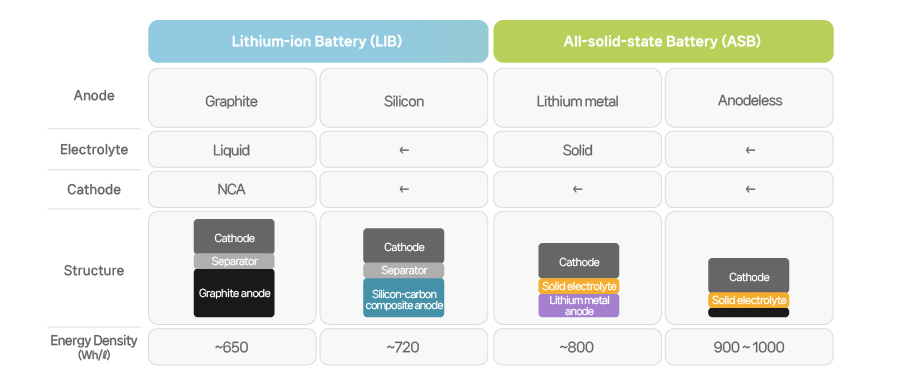

In general, there are two ways to increase energy density. One is to reduce the amount of materials that do not help increase energy density while increasing the amount of high-capacity active materials that help increase energy density. Battery components that do not help increase energy density are what we call inert materials, such as aluminum and copper foil used as the substrate for the cathode and the separator. Because all-solid-state batteries that use solid electrolytes don’t need a separator, we can expect higher energy density by removing it, but the desired effect is unlikely to be dramatic.

The second is to change the active materials of the cathode and anode. Until now, battery performance improvement has been mainly based on changing the cathode. But from now on, improvements in the anode will be the game changer to achieving high energy density in the next-generation batteries. Lithium metal batteries use lithium metal for the anode. Lithium-sulfur batteries use sulfur for the cathode and lithium metal for the anode. We can see that the materials used are different from conventional lithium-ion batteries.

[Difference between LIB and ASB]

Lithium metal and lithium-sulfur batteries are currently under active development based on ASB.

Lithium metal batteries increase energy density by using lithium metal for the anode instead of graphite and silicon materials. Experts expect energy density of 1,000 Wh/L, nearly double that of lithium-ion batteries. However, technological barriers are still there to realize mass-production because lithium metal is very unstable at room temperature and reacts violently with water. In addition, the lithium dendrite formed by the deposition of lithium particles on the anode surface can cause fire, so technologies such as special anode coating technology are needed to ensure safety.

Lithium-sulfur uses sulfur for the cathode and lithium metal for the anode. And there is a big difference in how lithium-ion is put into the cathode. Lithium-sulfur batteries create lithium sulfide (Li2Sn) by combining sulfur from the cathode and lithium from the anode. Through this chemical reaction, lithium-sulfur batteries are expected to have five times the energy capacity of lithium-ion batteries. In particular, lithium-sulfur is promising in terms of price competitiveness due to the abundance of sulfur.

However, the operating voltage of lithium-sulfur batteries is currently 2 volts, which is lower than that of li-on batteries, and their lifespan is estimated to be one-twentieth to one-fiftieth that of li-on batteries. Dendrite is also a concern, and researchers are working on adding special materials or creating protective films to address the problems.

[Comparison between Lithium-sulfur and Lithium]

All Solid Battery, coming soon

Have you ever seen a YouTube video of a battery being cut with scissors? When you cut a solid-state battery connected to a light bulb with scissors, there is no spark or fire. The light is still on. I can’t wait to see how our daily lives can change when all-solid-state batteries are widely spread around the world. But, where are we in research and development of all-solid-state batteries?

SAMSUNG SDI has been showcasing its all-solid-state battery (ASB) technologies at motor shows or battery-related exhibitions for decades, and is in a partnership with Samsung Advanced Institute of Technology and Samsung R&D Institute Japan Lab to jointly develop ASB technologies.

In March 2022, SAMSUNG SDI launched Korea’s very first ASB pilot line called ‘S-line’ at SDI Suwon Lab. It covers 6,500 square meters and includes battery-only electrode plates, solid electrolyte process facilities, and cell assembly facilities, which is estimated to increase energy density up to 800 to 900 Wh/L. SAMSUNG SDI aims to mass-produce ASBs by 2027 after testing it in EVs.

[SAMSUNG SDI’s ASB technology introduced in Nature Energy]